Application electrical scheme sharing of mask machine

2020-6-9

Sharing of mask equipment system application solutions (contributing to China's fight against the epidemic)

As the country with the largest mask production capacity in the world, Tian Yulong, chief engineer of the Ministry of Industry and Information Technology, once said that China's overall production capacity of N95 masks and medical surgical masks has reached more than 20 million per day. However, at the moment of the "epidemic" battle, some organizations predict that the daily demand for masks is at least 200 million.

Facing the huge gap between supply and demand, Essa Share Network launched the application plan of the control system of non-woven flat mask machine. The solution includes a series of products such as controllers, frequency converters, touch screens, and servo accessories. It can not only meet the needs of customers, but also help companies greatly increase production capacity and alleviate the difficulty of finding masks to a certain extent.

Non-woven flat mask machine process

First of all, it must be clear that at present, we need non-woven flat mask machines.

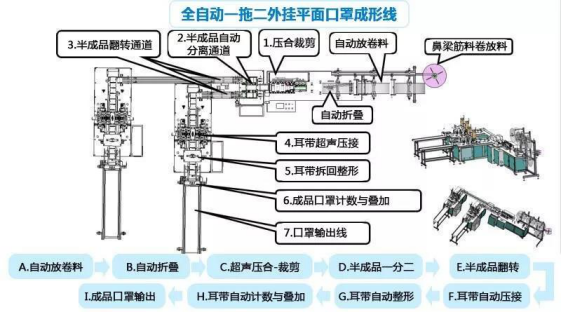

A flat mask is composed of a mask body and ear straps. Traditional mask equipment refers to a body machine responsible for forming and punching the mask body and an ear strap machine responsible for welding the ear straps. The efficiency of the body machine is relatively high (120-150 piece/minute), while the earband welding machine is relatively low (40-60 pieces/minute), in order to achieve the perfect cooperation between the output of the main body machine and the earband welding machine, it is necessary to match a body machine with 2 to 3 earband welding machines , in the fully automatic integrated equipment, generally a mask body machine is also connected with 2 to 3 earband welding machines.

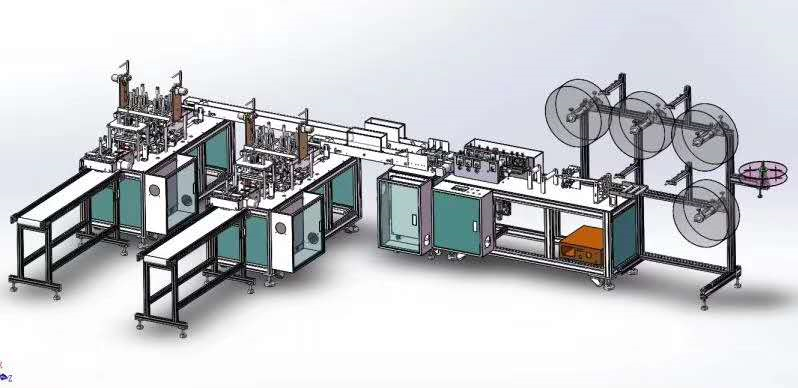

Figure 1 Process diagram of non-woven flat mask machine

Only high speed, high dynamic response, and high-precision drive products can rapidly increase production capacity

The raw material is passively dragged by the unwinding device, and the frequency converter realizes a relatively constant tension feeding; the mask is shaped through a special mechanical mold, and the corresponding pattern is printed out with the ultrasonic mold; With multi-station cooperation such as opening/closing clips, ear strap cutting, platform lifting, etc., the ear straps are welded on the mask; the two sides are folded and shaped, and the horizontal axis extends the model out of the structure to divide the mask into two halves and fold them together; welding workers The station and the folding and shaping station need to keep the platform and the raw material synchronously welded, and the servo system uses the electronic cam chasing and shearing function to realize the reciprocating operation.

Figure 2 Schematic diagram of the application of the electrical system of the non-woven flat mask machine

Figure 2 is a schematic diagram of the application of the electrical system of the non-woven flat mask machine. PLC and servo driver realize multi-axis control through EtherCAT communication bus, and communicate with touch screen through Modbus TCP; it has the characteristics of reliable stability, fast speed and high compatibility; the main conveyor belt is adjusted by frequency convertermotorThe conveying and stepping motors are turned over. During the welding and folding process, there are two axes that need to follow the main axis back and forth, and need to support more complex synchronization commands. The transmission is precise, the control is stable, and the speed is adjustable. Simple adjustment device, convenient refueling, high stability and low failure rate.