Optimized Air Gap Field Oriented Control for Induction Bearingless Motors

2022-9-6

The bearingless motor is the product of the combination of electromagnetic bearing and AC motor. It embeds the electromagnetic bearing winding that generates radial magnetic levitation force into the armature iron core of the rotating motor, so that the motor rotor has the ability to rotate and self-suspend support at the same time, effectively It solves the theoretical basis and technical key of realizing high-speed and large-capacity motors at the same time, and opens up a wider application prospect than electromagnetic bearings. In order to realize the stable suspension of the rotor, the radial magnetic suspension force must be effectively controlled, but there are couplings between the suspension force and the electromagnetic torque, and between the vertical and horizontal suspension forces. Since the magnetic levitation force is the result of the active unbalance of the air-gap magnetic field generated by the torque winding and the suspension winding of the bearingless motor, the air-gap magnetic field-oriented control must be used to solve the problem and ensure stable suspension operation.

There have been many researches on the air-gap magnetic field oriented control of induction bearingless motors at home and abroad. This control method can realize the stable suspension of the rotor under load and dynamics, but cannot realize the complete decoupling of the suspension forces in the two vertical directions. . Further analysis shows that the complete decoupling of the levitation force does not occur in the exact air-gap flux orientation, but only when it is oriented on a certain flux vector between the air-gap flux vector and the stator flux vector. , which means that real-time correction of the magnitude and phase of the air-gap flux linkage vector is required. This paper proposes the concept of a universal field-oriented controller, which can set the position of the directional magnetic flux vector by setting the parameter 'V/' to adapt to any existing field-oriented control methods. Although these studies are acutely Problems have been raised, but these ideas have not been used to form a solution to achieve complete decoupling of bearingless motors, and no operational analysis and countermeasures have been carried out for rotor parameter changes and the influence of ferromagnetic nonlinear saturation of the motor.

In order to deepen and realize this decoupling control idea, this paper firstly establishes the air-gap magnetic field-oriented control model of the induction bearingless motor, and conducts the simulation of stable suspension operation. Aiming at the actual working conditions of ferromagnetic nonlinear saturation, large dynamic and overloaded rotor parameters in bearingless motors, this paper points out that the amplitude and phase of the directional air gap flux must be corrected through nonlinear modeling and simulation. Furthermore, a novel dynamic solution control strategy to optimize the orientation of the air-gap magnetic field is proposed. At the same time, an optimized air-gap magnetic field oriented control system structure based on a general magnetic field oriented controller is also proposed, which solves the realization technology of tracking and dynamically adjusting the directional magnetic flux vector during operation, and provides the nonlinear dynamic required for the stable suspension of the induction bearingless motor. Decoupled control provides a way to achieve this.

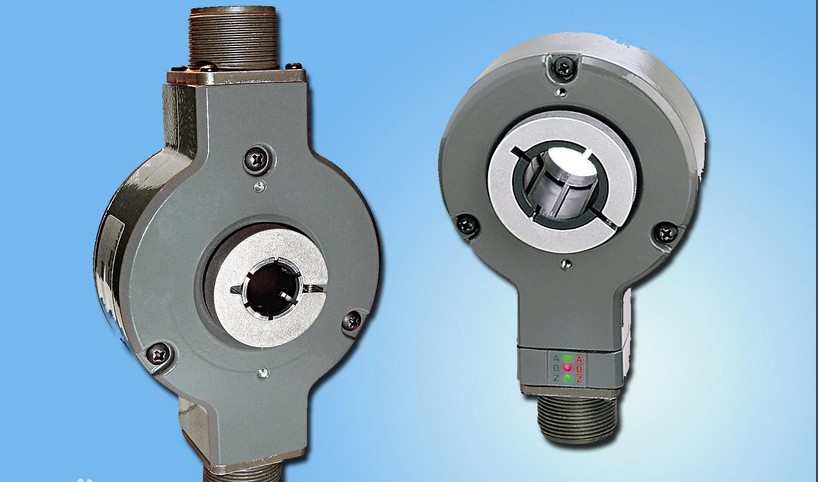

2 Air-gap magnetic field oriented control 2.1 is outlined as a schematic diagram of the induction type bearingless motor magnetic levitation force generation principle, wherein 1 and Chu are 4-pole torque windings, and sum is 2-pole suspension windings. If the corresponding current is applied to each winding according to the polarity shown in the figure, the 2-pole magnetic field will be superimposed with the 4-pole magnetic field, resulting in an increase in the air-gap magnetic density in area 1 and a decrease in air-gap magnetic density in area 2, and the magnetic levitation force of the uneven bearingless motor will be generated. The air-gap magnetic flux density of the schematic scale makes the rotor of the motor bear the magnetic levitation force along the direction, which makes the rotor float up. In order to realize the precise control of the levitation force, the key is to establish an air-gap field-oriented control model that realizes the decoupling of the bearingless motor system, including the levitation force model and the torque model. 2.2 Suspension force model According to the paper, if the influence of rotor eccentricity is ignored, the induction bearingless motor has magnetic levitation force in two orthogonal directions, horizontal and vertical, under the orientation of the air-gap magnetic field. It can be expressed as the flux linkage between the 4-pole air gap magnetic field and the torque winding; i4 is the excitation inductance of the torque winding, /.4 is the excitation current amplitude of the torque winding; /2l/, /2l/ respectively is the component current of the suspension winding in the synchronous speed coordinate system; r is the outer diameter of the rotor; / is the length of the effective iron core of the motor; where is the effective number of turns of the torque winding and the suspension winding in series; Ge is the average air gap length.

It can be seen that under the condition of air-gap magnetic field orientation, the magnetic levitation forces in the two vertical directions can be independently controlled according to the component currents of the suspension windings. In this way, in the suspension control of the bearingless motor, the suspension force value can be generated by detecting the displacement of the rotor, and then the current of the suspension winding can be calculated as follows. The winding voltage equation is the mutual inductance with the rotor; ⑴ is the power supply angular frequency; it is called the rotational speed angular frequency; D=d/d/ is the differential operator. The subscript is the torque winding or the 3-axis component, and *V and / are the stator and rotor quantities.

The air-gap flux linkage generated by the torque winding can be expressed as: Under the condition of air-gap magnetic field orientation, it can be obtained. Substitute equation (6) into the third and fourth rows of equation (3), and obtain /2=i2-M respectively; 2; = i, . /i,. is the rotor time constant; (= out - called the slip angle frequency, = the motor torque equation takes into account the relationship of formula (6) = general D 屮', then Us can be seen under the condition of air gap magnetic field orientation, adjust the torque winding The g-axis current can independently control the electromagnetic torque to realize the solution between the electromagnetic torque and the levitation force. The torque control principle under the orientation of the air-gap magnetic field is shown in the figure.

Influence, the operation simulation of the induction bearingless motor in the appendix under the air-gap field-oriented vector control is carried out. Among them, the correctness of the analytical model of the magnetic levitation force (1) has been analyzed and verified by finite element analysis using the special design software ANSOFT for the electromagnetic field of the motor.

In order to distinguish the change of the direction displacement of the rotor during the no-load starting process of the bearingless motor, the initial air gap eccentricity at rest is AFA; From standstill to 1420r/min, the overshoot of the speed is less than 0.6%, and the steady-state error of the speed is less than 0.3r/min. Under the directional control of the air-gap magnetic field, the rotor obtains a stable suspension, and the displacement in the 々 direction is stable within the range of ±60|im . (c) and (d) are the air-gap flux linkage amplitude and its phase %, change, respectively, and the phase angle refers to the phase deviation between the actual air-gap flux linkage and the orientation air-gap flux linkage.

3 Influence of rotor parameters and ferromagnetic saturation on suspension The above operation simulation is based on the ideal working condition of the bearingless motor, but in the actual operation of acceleration, loading or overloading, the sudden increase in the load causes the motor slip to increase, and the rotor circuit operating frequency If it rises, the skin effect will increase the rotor resistance, reduce the rotor leakage inductance, and increase the rotor current, resulting in an increase in the degree of motor saturation. These practical factors in operation all affect the suspension performance in the dynamics of a bearingless motor.

When the rotor resistance is increased by 1.5 times, the rotor leakage inductance is reduced by 20%, and the rotor time constant is reduced by nearly half, the motor suddenly adds a 5N+m rated load to the change of the rotor direction displacement. It can be found that after the load, the amplitude of the air-gap magnetic field generated by the torque winding is increased by 1.28 times, and the phase shift is 0.16rad, that is, the actual air-gap magnetic flux is shifted to the direction of the rotor flux, which destroys the original air-gap magnetic field. The precise orientation causes the rotor displacement to increase from ±60|jm to ±160|jm. In order to investigate the influence of ferromagnetic nonlinear saturation on the suspension performance, the air-gap magnetic density and rotational speed of the prototype obtained by the electromagnetic field calculation of ANSOFT software are given. The nonlinear relationship curve of the excitation component current of the torque winding, the rated operating point is at the excitation current/4, = 2.8A, and the air gap magnetic density is 1.2T. According to this nonlinear relationship and the levitation force calculation formula of Equation (1), the levitation force in a and the direction is obtained as The force no longer increases proportionally to the current. The maximum levitation force occurs when the excitation current/4, = 2.8A. If the excitation component current increases further, the levitation force will also decrease.

The excitation component current/4, under different torque windings are calculated, and the air gap flux linkage is affected by the torque component current/,. It can be seen that the air-gap flux linkage decreases with the increase of the torque component current /, , and the rate of decrease of the air-gap flux linkage becomes slower under the larger excitation current /4,. This is because the cross-saturation degree is further improved after the q-axis torque current increases, so that the shaft air gap flux decreases with the increase of the torque component current under the same excitation component current. In addition, the direction of the air gap flux is also It will change with the increase of the torque component current. Obviously, this will reduce the magnetic suspension force and affect the stable suspension operation of the motor.

The relationship between the rotor suspension force F and the torque winding excitation fe component current/4m and the suspension winding current/2 obtained by ANSOFT software. It can be seen that the ferromagnetic saturation in the bearingless motor is basically caused by two reasons: one is the direct effect of the suspension winding current required to generate the levitation force, and the other is the indirect effect of the torque component current of the torque winding required to generate the torque . Since the air gap magnetic field of the bearingless motor is mainly generated by the excitation component current in the torque winding, the indirect effect of the torque component current on the saturation is actually a manifestation of "shaft cross saturation.

In order to take into account the influence of the above air-gap magnetic field saturation into the suspension force model through the relationship between the air-gap flux linkage and the rotational speed component current of the torque winding after the ferromagnetic nonlinear saturation shown, the simulation study of the influence of saturation on the rotor suspension can be carried out. . When the load is suddenly doubled from zero to lON.m, the displacement of the rotor direction and the amplitude and phase of the air-gap flux linkage change, as shown. It can be seen that due to the increase of 々, the air-gap magnetic field generated by the torque winding is saturated, the magnetic flux amplitude is reduced by 0.81 times, and the phase shift is 0.15rad ahead, so that the air-gap magnetic field cannot be accurately oriented, and the rotor gap flux linkage is oriented. On the basis, according to factors such as rotor parameter changes and the influence of ferromagnetic saturation of the motor, the size and phase of the air-gap flux linkage for orientation are corrected, and an optimized air-gap magnetic field orientation method is found to ensure complete dynamic and overload conditions. Decoupling.

4 Optimizing the air-gap magnetic field-oriented control strategy This is a new type of dynamic directional decoupling control that is different from the standard air-gap magnetic field orientation and needs to be implemented by a general magnetic field-oriented controller. The principle block diagram of the general magnetic field orientation controller is shown in 0. A coefficient ', /" is defined in the controller. By choosing different values, the magnetic flux vector * for orientation can be flexibly selected. Table 1 gives the corresponding "values" the magnetic flux vector.

Using the concept of general magnetic field director, it is possible to deal with the changes in the amplitude and phase of the air gap magnetic flux vector caused by actual factors such as changes in the rotor parameters of the motor and the influence of magnetic saturation; by selecting appropriate values, the magnetic flux of the controller can be dynamically changed vector to achieve accurate orientation after real-time correction of air gap flux linkage.

1 The variation law of the phase advance angle of the air-gap flux linkage when the rotor resistance and leakage inductance change are given. The resistance and leakage inductance of each phase of the rotor in the figure are per unit values. It can be seen that with the increase of rotor resistance and the decrease of leakage inductance, the actual air-gap flux linkage in the motor will lag behind the selected flux linkage vector, that is, it is biased towards the rotor flux linkage direction, as shown in 2, J and 2 represent The relationship between the choice of the median value of the general field-oriented controller and the phase shift angle of the flux linkage is presented. When <1, with the decrease of , it moves in the direction of the rotor flux linkage vector r, and the phase of the air-gap flux linkage becomes lagging; (> 1, as the increases, it moves in the direction of the stator flux linkage vector, and the air gap The phase of the flux linkage becomes advanced. This lead angle can be used to offset the phase shift of the air-gap flux linkage caused by the parameter change, so that the air-gap magnetic field can be re-oriented accurately.

The effect of 2-value and phase A similar method can be used to correct the amplitude and phase of the air-gap flux linkage for the effect of ferromagnetic saturation. An optimized air-gap field-oriented control system for induction bearingless motors considering rotor parameter changes and saturation effects is shown in Figure 3. In the figure, the air-gap flux linkage value and the measured value obtained by the air-gap flux linkage observer are used to realize the correction of the amplitude and phase and the selection of the parameter value of the general magnetic field oriented controller.

3. Block diagram of the optimized air-gap field-oriented control system Based on the optimized field-oriented control model of 3., the steady-state and dynamic simulations of the bearingless motor under overload conditions are carried out. Taking the change of rotor parameters as an example, when the rotor resistance increases by 1.5 times and the leakage inductance decreases by 20%, the air gap flux linkage I// is relative to the flux linkage I//:. will lag by 5.16° (1). In order to correct this phase shift deviation, the general magnetic field controller selects <=1.05. And because of this change, the air gap flux linkage increases by 1.28 times, so the air gap flux linkage when the amplitude is corrected will be reduced to 1/1.28 of the original. The simulation result after this automatic correction is shown in 4.

4. Simulation results of optimized air-gap magnetic field-oriented control when the rotor time constant is reduced and a sudden load is applied. When the load is suddenly overloaded from zero to lON.m, the saturation phenomenon is obvious. The rotor suspension performance corrected by the optimized air-gap magnetic field-oriented control method is as follows: 5 shown. Due to the optimized air-gap magnetic field orientation control, the dynamic correction of the air-gap flux linkage vector for orientation is realized, and the influence of practical factors such as rotor parameter changes and ferromagnetic nonlinear saturation on the motor suspension performance is effectively eliminated. Dynamic decoupling of suspension forces under overload.

5. Simulation results of optimization of air-gap magnetic field orientation control when ferromagnetic saturation is considered. The deviation of amplitude and phase appears in the vector. In this paper, the phenomenon is deeply studied and analyzed through simulation, and the law is revealed. At the same time, based on the concept of general magnetic field oriented controller in AC speed regulation technology, an optimized air gap magnetic field oriented control strategy and its control system are proposed. The bearingless motor has large dynamic and dynamic complete decoupling control under overload, so that the bearingless motor can still obtain the ideal decoupling control of the suspension force and the stable suspension operation of the rotor under actual operating conditions, which provides an implementation approach for the operation control of the actual system. .